I thought I'd have a go at a blog post about the gouges and the other cutting tools I use when making my lino prints. Once again this is about my personal experience with different tools and about how I use them to create my own work. Others may prefer different tools and different ways of working. There's no definitive best tool or right way to use it.

Finding the right combinations of cutting tools for a relief printer is one of the hardest choices to make. As with many things, its a play off between price, quality and how much you want to invest. There is a very wide array of brands and choices. The tools also need to match the way in which you want to work and how you may physically use them.

Most people start with the plastic or wooden handled versions of cutters with replaceable blades. These are good as starting tools as long as they are sharp. I used them, to teach relief printing, in a secondary school for decades. It was always a time consuming task, to ensure that the blades were sharp and properly attached to the handles. The blades can be honed/sharpened but I found that if they'd been used for potato printing (or combat!) they were only fit for the bin!

The step up from the replacement bladed gouges is to use fixed blade cutters. As you become confident that linocutting is for you and you want to take your practice to the next level, it's a logical step. It does make cutting easier but you need to choose a a combination of cutters that suits you and the way you work. Most manufacturers offer quite expensive sets of several tools. I don't usually advise people to buy these. There are always a couple of tools in the set that never/rarely get used. My advice is to identify the two or three tools that you already use most (assuming you are using the replacement blade types of cutters or sharing somebody else's tools) and then to start by just gradually buy those.

A brief video!

These are my experiences, over the past decade or so, with different types and brands of tools.

Replacement Blade Tools

These tools are a good way to start with lino cutting. They are usually fairly cheap. One thing I know from being head of a, short for cash, Art Department in a secondary school in the Welsh Valleys, is that the blades can usually be sharpened and honed.

The ones shown below are the red plastic Essdee handle and cutter, Abig, light wooden handle cutter and (my favourite) a vintage William Mitchell handle. There are other manufacturers, I know the Arteina tools are well made (as are all of their range).

Pros - Usually quite cheap. A good way to discover which blade shapes suit the way you want to work. Cons - Strangely I've found there can be some variation in the quality of blades within the same manufacturer. They don't stay sharp for long. If you only have one handle, you need to be constantly changing blades. I have never, ever, used the straight cutting blade provided in every set!

Pfeil

These tools are a very popular choice of gouge for many lino or wood relief printers. The steel seems to hold an edge for a long time. I've managed to keep mine going for years with a good polished edge without any sharpening. They just need honing each time they are used and maybe every couple of hours if working all day.

They can be bought individually or in sets. My comments about buying gouges in sets definitely apply to this make. The codes for the blade sizes and shapes can be a bit confusing, there is a logic to it but here's a chart.

These are the blades I use 8/3, 12/1, 11/0.5 and 11/2. I could probably do without the last one but its good for certain textures. I have several much wider, flattish, vintage 'U' gouges, so I haven't bought a Pfeil one.

Pros - Solid and well made. small enough to fit most hands, with the flattened mushroom shape that fits well into the ball of your hand. The steel takes an excellent and lasting edge.

Cons - Fairly expensive (but if looked after properly, they should last a lifetime).

Matthieu Coulanges

Matthieu Coulanges makes a high end range of hand made tools for different print techniques. It's a French company (you may have guessed). I also have some of the intaglio tools. All are of a very high quality. The handle are well balanced and beautiful to use and to look at. You can choose from a range of woods for the handles. Mine came with these natty blade guards. They are very slightly bigger than the Pfeil gouges. Have a look at the website. There is a link at the end of the blog. It's great to just window shop! Save up your pennies and check out the import tax (thank you Mr. Johnson).

Pros - Just beautiful! Hand turned handles and good steel that stays sharp. Brass ferrules. Well balanced. you can even chose the type of wood (or combinations of wood) you would like for your handles.

Cons - The price. I've resharpened my small V gouge and it seems to cut better now, I think the angle of the blade was very slightly obtuse. If you are in the UK, importing them from France isn't as simple as it used to be.

Vintage Mushroom Handled gouges, T N Lawrence, H Taylor and others

These are some of my favourite gauges. Many of my tools must be around a hundred years old. I think most of mine were manufactured in the UK (when we had a proper manufacturing sector). T N Lawrence is still going but no longer selling their own tools (and just recently taken over by Jacksons!).

They can be a bit variable but are generally the finest made tools available. I find that the older steel keeps an edge very well indeed but there can be small pockets of impurities. The original handles usually have quality brass ferrules.

In the past I've found them in junk shops etc. but also on eBay. The ironic thing is I've then used Lawrence's excellent sharpening service to get some of their own old tools, that they no longer supply, into the best possible condition. I can sharpen tools myself but it's difficult to beat the convenience of the service.

UPDATE. Lawrence have just been taken over by Jackson's. It seems the sharpening service is continuing and is now available on both websites. I think the price has increased slightly.

For me, the best of these old tools , are the best gouges I have found anywhere. It's a shame they are becoming less easy to come by, as people start to realise their worth (this blog won't help!).

Pros - Very fine and mostly well made tools. Great steel, they hold an edge very well. They are smaller and usually fit smaller hands better and are more maneuverable. The finer 'V's and 'U's are better than any other fine tools I've found. Even with professional sharpening they can be cheaper than many tools on the market. Cons - They nearly always need some attention to get back into fully working order. You may need to use a professional sharpening service to establish a proper edge.

Powergrip

I've only tried a couple of these Japanese Powergrip tools. They seems very well made and I know lots of people create fantastic work with them and enjoy using them . They are good value for money and the steel is great. They just don't seem to fit my hands well and the 'V' blades are sharpened at a different angle to my other tools. I think that's why I find then difficult to cut curves.

Pros - A good price and well made. Cons - They may not suit everyone.

Japanese Cutters

These economy Japanese cutters from Intaglio Printmakers are a good step up from the replaceable blade sets. Currently they are available for around £5 each. I purchased several of them for teaching classes. They work fine and the blades hold an edge very well. They have the longer Japanese style handles that may not suit everyone because they have to be held in a different way. I have contemplated cutting the handles a bit shorter but that just seems wrong.

Pros - Good quality for the price. Cons - Limited sizes available. The handles might not suit everyone.

Sharpening/Honing

There is a very important difference between these two terms and they are sometimes mixed up

Many others have written about sharpening cutting tools, just do an online search. I'm not going to start to try to explain the technique in words, it's probably much easier to work from videos. Essentially, it's never a good idea to start changing the angles of blades unless you really know what you are doing. I've found that my gouges only need sharpening very occasionally. Several that I've had over 5 years have never been sharpened. Only if a blade is damaged, misused or angle of the edge needs to changed is it really necessary. If you are unsure about sharpening, busy, or just a bit lazy (like me) I would recommend the Lawrence sharpening service. I've mentioned the service more in the section on vintage tools and I'll post a link at the end of the blog.

In contrast to sharpening, I hone my tools at the start of each cutting session. You can usually feel that a gouge is starting to lose its edge while working. More pressure is needed to cut. That's when it's easy to lose control, to make a mistake in cutting, or worse, to have an accident. It takes a couple of minutes to re-hone the edges and get back working. I have a (Flexcut) Slipstrop which is great for the smaller gouges. For the larger ones I use a nice thick piece of leather, along with some honing compound.

Rub a bit of honing compound on to the leather then only ever draw the edges along the surface of the leather, never push. Keep the angle of the cutter, as exactly as possible, the same as the angle of the edge you are honing. If it's a curved gouge you will need to rock it from side to side as you draw it over the leather. You are trying to polish the cutting edge. it should have a mirror like surface.

This polishing of the cutting edge with make a micro bur of metal onto the inside edge of the blade. This is where the Slipstrop can be handy. Find which profile, on the sculpted wooden side, best fits the inside surface of the gouge. Rub a bit of compound along the profile and then holding the gouge flat against the profile draw the edge (don't push) along the shape to remove the bur. With practice, the whole process takes a minute or two and you will be surprised the difference it can make. If you do it just right, it's quite scary how sharp the gouge can get.

Storage

For me there are two options. If I'm storing gouges in a wooden box, I like to put half corks on the end of each blade. It stops them being damaged and helps to stop your fingers being damaged, when you are riffling through your tools, looking for a particular gouge! One of my ex-pupils very kindly made me a tool roll for my gouges, so the ones I use most often, are stored in there.

Cutting with a Craft Knife

A good strong craft knife is an important tool for a lino printer.

Cutting lino to size and cutting paper and board are pretty basic needs.

In addition, I find when I need to cut lots of complicated small shapes, it is sometimes quicker and more accurate to use a knife.

It's necessary to cut with the blade at an an angle. Imagine the v shaped line cut by a 'V' gouge; with a knife you have to cut both sides, one after the other. Cutting small shapes, you angle the blade and hopefully the whole shape drops out. On larger shapes I find myself cutting 'V's around the edge of the shape and then using a flat 'U' gouge to clear out. I hope you can see this from the short video below.

I was an art teacher for a few decades, so I'm well aware of some of the health and safety implications of using a knife like this... as well as the obvious 'be careful it's a sharp knife!'. It's important not to put sideways pressure on the knife that may snap the blade. A blade typically breaks into three pieces. The big bit left in the knife, the point that may stay in the work, and a middle section that can fly out at speed! I use the yellow snap bladed, sliding knife, that's shown above. I keep the blade as short as possible in use. I've never snapped the blade myself but I have seen it happen to others. I wear reading glasses but I would be thinking of safety goggles if I didn't.

Starting Out

So you've got your tools ready, sharp and organised. Now to start using them. It's best to look at some of the videos and to experiment for yourself about the actual grip that you use when cutting. It depends on the tool and your personal preference.

When I teach I try to advise students to always cut away from themselves. I have, in the past, recommended the use of a bench hook, to stop the lino moving. Recently I've been using small pieces of anti-slip matting, it allows the lino to be turned around more easily during cutting.

You may have noticed me cutting towards myself in the video earlier. When I'm working on a large piece of lino, that's also mounted on a large MDF registration board, it becomes a bit impractical to keep turning it round (it will be larger than A1 size). It really only works safely with smaller gouges and you do have to concentrate... but it works for me (and so far no major lacerations!)

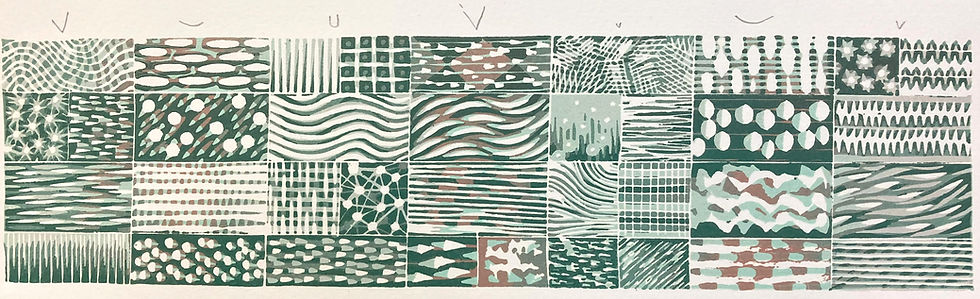

A good exercise to get familiar with gouges and cutting techniques, is to do a test piece using some scrap lino and paper. It's a good chance to experiment with the effects that a gouge can make - push the boundaries a bit without messing up a serious bit of work.

Divide up a waste bit of offcut lino with some thin cut lines, one for each of your gouges.

I've not long finished this test piece. In this first set of photos, I printed it simply in black. I've used seven different gouges. I've just shown a few of the possibilities in making textures and patterns, there are many more. I like to do this exercise occasionally, it's easy to get lazy and limited to just a few cutting techniques, when working on a designs.

For those interested in reduction linocut techniques, this simple exercise can be extended. I'm not going into detail about registration techniques here (that's about making sure each round of overprinting lines up exactly, I may need to do another blog post about that specifically) but I printed out the same piece of lino in light tones onto a few bits of paper.

Then I've cut back into the lino plate a couple of times. each time overprinting onto the original pieces of paper with slightly darker ink.

Out of interest, instead of making the ink gradually darker, which is my usual technique. The example below shows some of the nice effects you can get from the same layers of cutting and printing, where I have used a spare print, from the first exercise, with a black first layer.

Lastly

An essential equipment whenever I teach a class. I still make the occasional slip myself, usually when I'm rushing or tired. This old wisdom is also true... 'You are more likely to cut yourself with a blunt tool!... If you have to use a lot of energy to push the gouge and it slips, it's more likely to do damage.

Please feel free to add comments and ask questions!

UK Suppliers

Hawthorn

Intaglio Printmakers

T.N. Lawrence

Handprinted

Jacksons

Cornelissen & Son

Matthieu Coulanges

Sharpening Service

Comments